What Is Takt Time? Importance & Calculation

Want to measure your productivity with real data? A Takt Time calculation is what you need! Follow on to learn how to calculate it for your business activities.

To manage any production of a product or service, it helps to know how much time you are spending. Takt time can help you understand the productivity of your business activities in a clear way.

In this guide, we’ll learn how to calculate your takt time proficiently to take your business to the next level.

Here’s What We’ll Cover:

Cycle Time vs Lead Time vs Takt Time

What Is Takt Time?

In a nutshell, it is the amount of time spent creating and delivering a product or service to a customer.

For example, let’s take a car manufacturer. The manufacturer receives an order for a new car. From the time that the order comes in, to the time that the order is delivered, there are 24 hours of takt time. That is, it takes 24 hours to process, create and deliver the car to the customer.

Another way of explaining it is the amount of time it takes to fulfil customer demand. This is to ensure a continuous flow of products are made to meet the needs of your customers in a timely manner.

The word “takt” is German. It means to beat or pulse. You can think of takt time as the metaphorical heartbeat of your company. The humming tick of products in and products out.

Calculation For Takt Time

Takt time formula is as follows:

Takt time = Total available production time/Average customer demand

Available production time would be the amount of time you or your employees have to work on fulfilling customer demands. So essentially your productive work hours. That means deducting minute breaks. That could be lunch breaks, shift changeovers, bathroom breaks etc.

So say your company operates an 8-hour workday 5 days a week. That would be 480 minutes of available time if no one ever needed to eat or pee. So adjusting for breaks, let’s say you have 400 available production minutes per week.

Now for customer demand. How many orders do you receive per week? For our fictitious example, let’s say 50. That’s your demand rate.

The calculation would then be 400/50 = 8 minutes of takt time

The takt time is all about meeting customer demand. So if your customer demand increases then it’s a good opportunity to review your cycle time to meet customer needs efficiently.

Why Is Takt Time Important?

It is important for many reasons:

- It reduces waste in the production process. If you can identify what may be holding you back from achieving takt time, you’ll make your process even more efficient.

- It helps alleviate storage costs. This is by reducing the likelihood of overproduction.

- It helps create a continuous workflow with minimal wasted moments.

- It helps you quickly identify broken elements in the system when they slow down.

Cycle Time vs Lead Time vs Takt Time

These production terms get muddled up all of the time when it comes to product timelines. Here is a shorthand to clarify.

Cycle time

Cycle time is the amount of active time your team spends on a customer order. So this would be the actual manufacturing process and any waiting times in between. It is possible to affect the cycle time by changing processes in your system. However, the takt time, in this situation, would remain the same.

Lead time

Lead time is the amount of time from when the order arrives to the finished product. So this includes the processing time, manufacturing process, wait times and delivery.

Takt time

Takt time accounts for the continuous flow of products to be made. It’s the maximum amount of time you could spend making customer products in order to keep order fulfilment on schedule.

It’s often confused with cycle time. Your cycle time and takt time should not be the same. It’s an impossible standard to set. Experts generally recommend that your takt time is 5-17% longer than your cycle time. This is because you need to account for natural human inefficiencies and breaks in your work.

In short, your takt time is the maximum amount of cycle time your company can manage without faltering on customer demand.

Key Takeaways

The key to understanding takt time is to recognise it’s all about customer satisfaction. Will they be getting their products on time with your current process? What is your capacity for fulfilling orders? That’s what you’re examining here.

For more guides like this one, check out our resource hub!

RELATED ARTICLES

What Are Performance Metrics? Definition & Examples

What Are Performance Metrics? Definition & Examples Decision Matrix Analysis: Overview & How to Use for Business

Decision Matrix Analysis: Overview & How to Use for Business What Is a Floating Charge & Fixing Charge? Difference

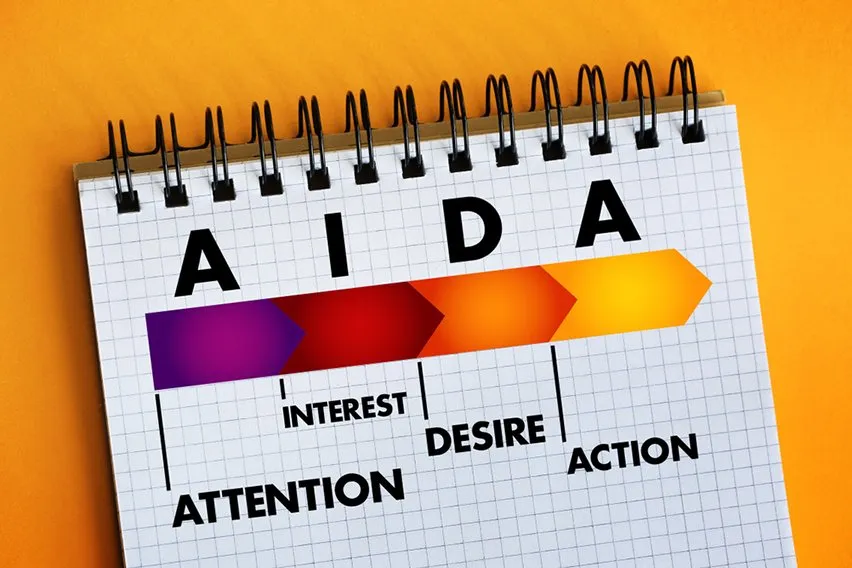

What Is a Floating Charge & Fixing Charge? Difference What Is the AIDA Model & Its Best Practices to Apply in Real World

What Is the AIDA Model & Its Best Practices to Apply in Real World Top 7 Small Business Trends You Need to Know

Top 7 Small Business Trends You Need to Know How Brexit Affects Businesses in The UK?

How Brexit Affects Businesses in The UK?